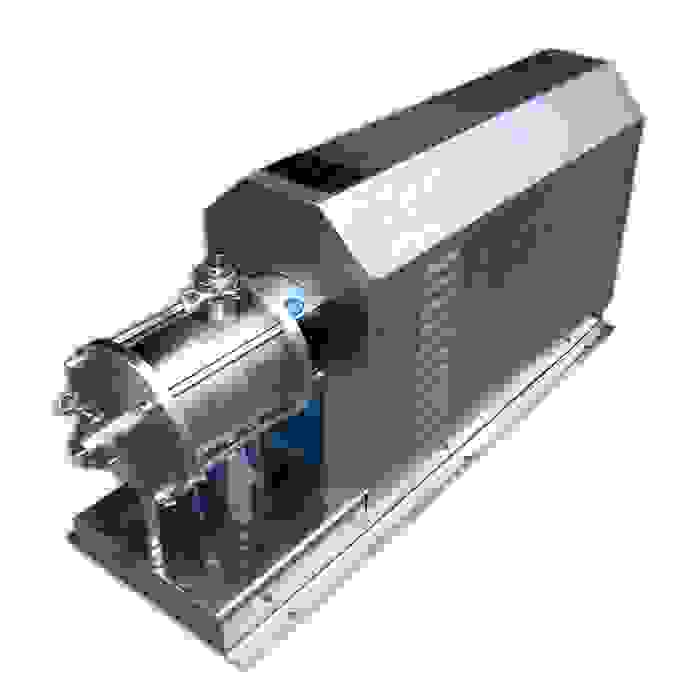

PerMix In-Line Emulsifiers

PerMix In-Line Emulsifiers are engineered for performance, value, and sustainability, all while maintaining a budget. PerMix then backs our In-Line Emulsifiers with the best warranty in the industry. PerMix In-Line emulsifiers are available in a Signle Stage Emulsifer, up to a Four Stage Emulsifier.

PerMix In-Line Emulsifiers: 1 to 4 stage Type

PerMix In-Line Emulsifiers Additional Information

PERMIX IN-LINE EMULSIFIER INTRODUCTION:

PC - Inline Emulsifier Mixer is a high shear mixer for inline or continuous operation. In the Inline process, the mixer is installed outside the tank. This makes it easy to be built into an existing production line with normal inlet/outlet connections. In the case to deal with liquid with a low viscosity, the inline mixer can pump the liquid without an additional pump. That is why it is also called High Shear Pump. The mixer can be used to deal with the product in a single pass or with several circulations to make the product better. Different from a Batch High Shear Mixer, the mixing occurs in the mixing chamber, thus energy is introduced onto materials in the most efficient way. This also cuts the process times by up to 90%

PERMIX IN-LINE EMULSIFIER WORKING PRINCIPLES:

Step 1. When the rotor is driven by the motor, it rotates at a very high speed of several thousands rpm. A powerful suction is generated at its center and draws both solids and liquids from the inlet pipe into the working chamber.

Step 2. Centrifugal force leads the materials to the periphery. Materials are subjected to intensive squeezing and milling at the precision machined clearance between rotor and stator. High pressure is created there too due to the gathering of materials, which makes the impact between particles more remarkable.

Step 3. Followed is another intense hydraulic shear as the materials are forced out through the openings in the stator at very high velocity. When material particles arrive outside of the stator, they tend to explode into thousands of even smaller ones as the pressure drops down sharply.

Step 4. Fresh materials are continually drawn into the stator-rotor maintaining the circulation or single-pass flow

PERMIX IN-LINE EMULSIFIER STATOR/ROTOR SYSTEM:

PerMix also designs two types of Stator & Rotor systems: K type and V type. Both have several sub-types. These designs of stator & rotor systems offers more selections for our customers to choose the most suitable one to deal with their specific liquids and solids.

Multi-stage & Multi-row Stator/Rotor:- Rows: Every stator and every rotor have one or several rows of "teeth" (K-type, stator and rotor), or "blades" (V-type, rotor), or "screens" (V-type, stator). - Stages: PerMix supplies PC1 series Single-stage Inline Mixer, and PC3 series Multi-stage Inline Mixer. PC3 series Inline Mixers have three sets of stator & rotor. Standard PC3 Mixer includes sets of coarse, intermediate and fine stator & rotor assemblies. PC3 Series Inline Mixer is applied to deal with difficult-to-disperse materials, or when customers require single-pass processing. The multi-stage (usually 3-stage) inline mixer has 3 sets of stator/rotor systems to enhance its shearing performance. This design dramatically reduce processing time, and in some cases only one pass through the mixer can lead to satisfied products. Depending on the materials to be processed and customer requirements, for each stator/rotor, there can be only one row, or multi-row of teeth. Besides, PerMix provides coarse, medium and fine teeth to achieve different shearing intensity.

Special Design with Ultra-high Speed:PerMix designs the ultra-high speed inline mixer with the tip speed of about 40m/s. The ultra-high speed inline mixer is belt driven to increase the rotation speed of the rotor up to 12,000rpm (Model: PC-1/60, pilot size).

THERMOSIPHON FOR DOUBLE MECHANICAL SEALS:

The thermosiphon is used to store and cool the buffer liquid for the double mechanical seals, operated as a closed circuit. It is able to compensate the leakage of the buffer liquid at the double mechanical seals to avoid drying running of the seals, thus improve the performance and duty life of the seals. The buffer liquid flows to the thermosiphon from the double mechanical seals with the principle of Thermosiphon Effect (or by forced circulation), and returns to the seals being exchanged and cooled. The thermosiphon is built in SS304 or SS316L, with pressure gauge, sight glass, all necessary connection nozzles and brackets for easy installation. The tank can be built with or without cooling coil with the purpose to cool the buffer liquid by cooling water.

APPLICATIONS:

- Food & Beverage

Reconstituted milk, Salad dressing, Mayonnaise, Ice cream, Cheese, Yogurt, Fruit juice

- Pharmaceutics & Biology

Drug synthesis, Vaccine, Fat emulsion, Injectable suspension, Veterinary medicine, Cell extraction

- Cosmetics & Daily Care

Detergent, Body gel, Shampoo, Cream, Lotion, Tooth paste, Soap

- Chemicals & Oil Industry

Synthetic rubber, Resin, Bitumen, Silicon oil, Dye, Pigment, Coating, Ink, Nano material

Learn More

PerMix engineers & manufactures mixers of all types for all industries. Since 1954 PerMix has been leading the industry.

PerMix In-Line Emulsifier Photo Gallery

PerMix In-Line Emulsifier Video

PerMix Single Stage In-Line Emulsifier With Powder Induction

PerMix 3 Stage In-Line Emulsifier Video

PerMix Three Stage In-Line Emulsifier

Copyright © 2019 PerMix North America - All Rights Reserved.

INTERNATIONAL OFFICES & SUPPORT

CHINA OFFICE: No.1888, N. Shengxin Road, Jiading, Shanghai, 201807, China | Tel: +86 133 911 68218 | Email: aaron.h@permixtec.com | Website: www.permixtec.com

WESTERN HQ / OFFICE: 230 Hazait St. Adi, 17940 Israel | Tel: +972-54-908-0144 | Email: srugoa@permixtec.com | Website: www.permixtec.com

NORTH & CENTRAL AMERICAN HQ / OFFICE: Chicago, Illinois, USA | Tel: +1 630-649-1357 | Email: John.paul@permixtec.com | Website: www.permix-mixingna.com

SOUTH AMERICAN OFFICE: Atuel 1162, C1437EQD CABA| Tel: +54-9-11-35374801 | Email: gonzalo.villagra@permixtec.com | Website: www.permixtec-sa.com

RUSSIAN OFFICE: HaRav Fatal 9, Jerusalem 9743009, Israel | Tel: +972 54 5990732 | Email: goldlon@mail.ru | Website: www.permixtec.com

FRANCE OFFICE: 63 rue André Bolier, Lyon 69007, France | Tel: +33 4 74 94 43 20 | Email: infos@edsmix.fr | Website: www.edsmix.fr

Copyright © 2020 PerMix North America - All Rights Reserved.

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.